Reliable steel services in Winchester

You can rely on M J Ellis Manufacturing for a range of steel assembly services. Based in Winchester, we serve customers across Southampton, Salisbury, Portsmouth, Basingstoke and South London.

Talk to us

Opera House, West Horsley.

This is a job we carried out for R J Smith & Co at West Horsley and was 312 tonnes of steel on the mainframe, which was fabricated and erected in 11 weeks from drawing sign off. In addition the roof steelwork was completed to EN 1090 Execution Level 3 standard which specifies increased levels of testing and traceabilitiy . All 56 tonnes of fittings were produced in-house with our 8m x 2m plasma profiling machine.

Northampton Street, Bath.

This is a 25 ton steel project we did for Ken Biggs Contractors Limited. Due to extremely limited space on site we had to do a part road closure to site the crane and the steel before it was erected. M J Ellis took responsibility for full contract lift. MJE liaised direct with Bath Council to arrange and book lane closure. Where the crane was required to sit there where old roman vaults under the road. Therefore MJE had to work with engineer and scaffold company to come up with a support design to support vault roofs from collapsing when crane sat on top. The crane had to be position to the millimetre when set up to ensure it was incorrect place and didn’t go through vault roof. Steelwork had to be unloaded off the lorry parked in the road whilst site management worked to control cars in the lane still used by motorists. Steel was set down in closed of section of road. Due to narrow confinements and steelwork starting from basement level we had to lift cherry pickers into the site build our way out.Once we had gone as far as we could we had to lift the cherry pickers out and finish erecting the steelwork from the road.

Brewery Square, Dorchester Feature Aches in Steel.

This striking new development in the centre of Dorchester was just the kind of project that we excel in, producing a bespoke structure, from drawings, in this case formed from 15mm steel plate. When finished the entire installation weighed an impressive 48 tonnes. M J Ellis worked alongside Sapphire Balustrades on this challenging project.

Our partnership on the design meant the glass balustrade system from Sapphire would fit perfectly onto the balconies behind the arches themselves. The finishing touch, to achieve the design objective was a coating of MIO (Micaceous Iron Oxide) in brown, which gave an attractive faux rust impression and extremely long-term weather protection.

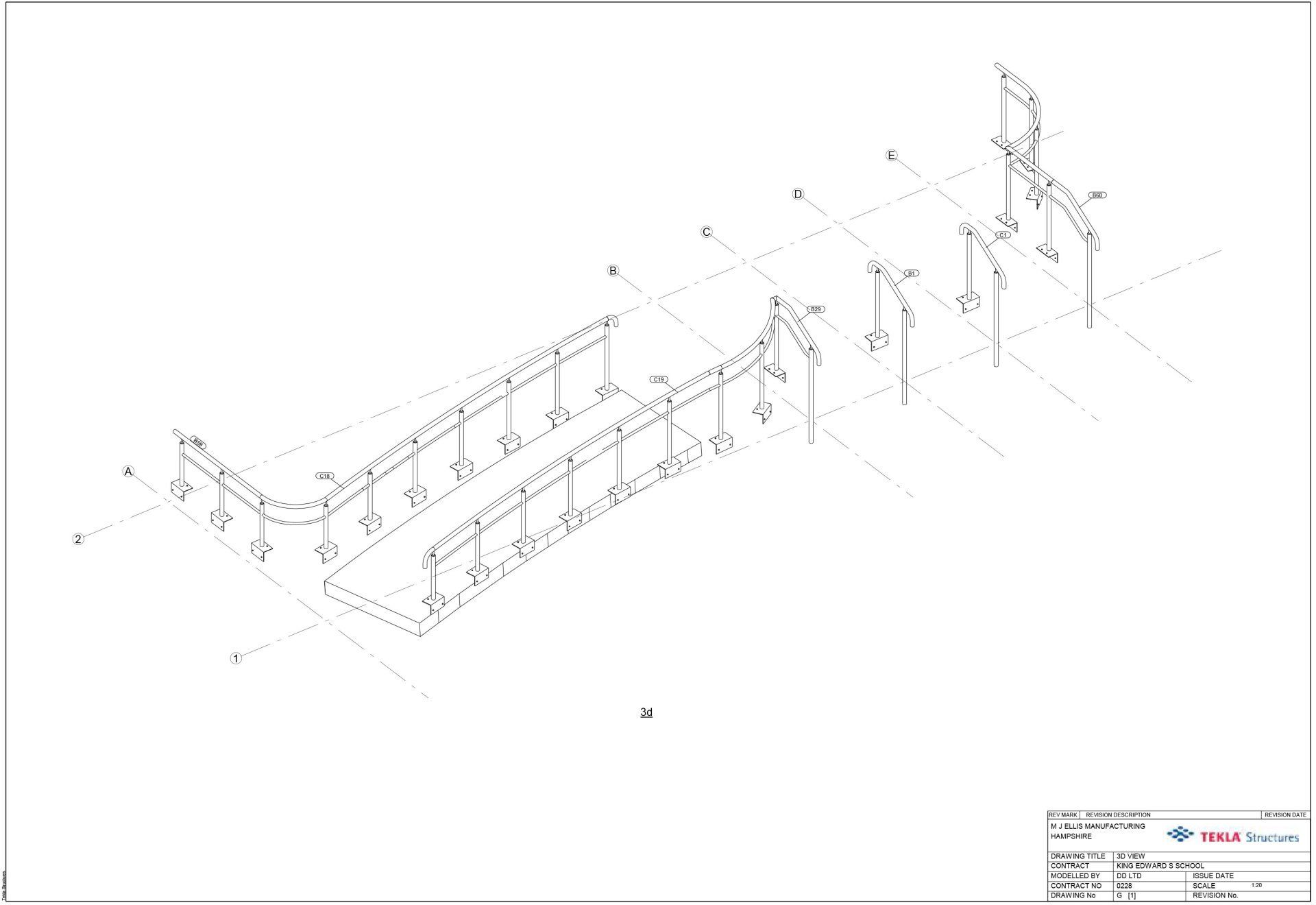

King Edwards School, Southampton Stainless Steel Balustrade.

Our ability to produce a bespoke solution directly from drawings and to do it within a very short time frame was tested on this project. The contractor needed to complete the works over the schools short summer closure period. Our brief was to design and fabricate contemporary stainless steel balustrade in a way that would both harmonise with the ground works and provide a ‘first time’ fit. Working straight from the architect’s drawings MJ Ellis produced the balustrade whilst the ground works were in process and installed the steel in the final week of the project. The result was a perfect fit and a project finished right on time.

For top-quality steel assembly services.

01794 388516

Call us on